Furfural (58.6% yield) and cellulose-enriched residue (>90% glucan recovered) are coproduced with 89.3% glucose yield in a MTHF/aqueous AlCl3 system. (Image: pubs.acs.org).

Coproduction of Furfural and Easily Hydrolyzable Residue from Sugar Cane Bagasse in the MTHF/Aqueous Biphasic System: Influence of Acid Species, NaCl Addition, and MTHFResearchers from Xishuangbanna Tropical Botanical Garden (XTBG) of the Chinese Academy of Sciences chose sugar cane bagasse (one of the commonly used biomass in furfural industry) as raw material for one-pot production of furfural and cellulose-enriched residue using AlCl3, FeCl3 and HCl as catalysts.

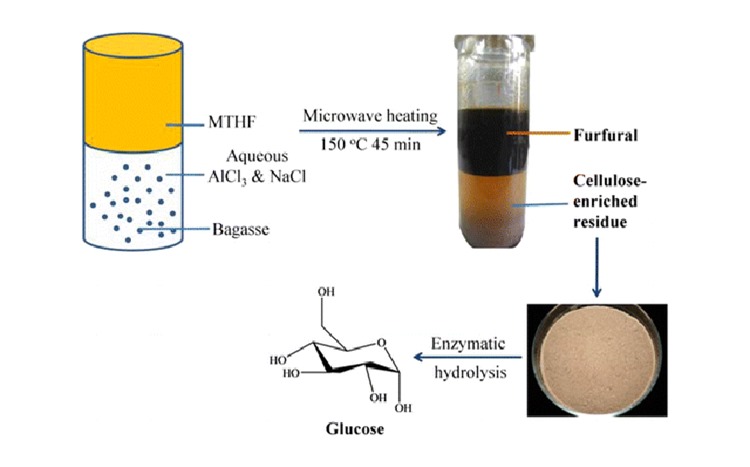

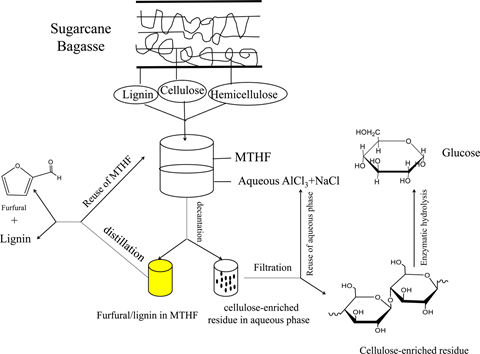

They studied the degradation of sugar cane bagasse in a single aqueous system and in a 2-methyltetrahydrofuran (MTHF)/aqueous AlCl3 biphasic system. Their aim was to develop a process for the simultaneous production of furfural and easily hydrolyzable cellulose.

They found that conversion of bagasse in aqueous solution with FeCl3 and HCl benefited furfural 1 production from hemicellulose but degraded cellulose seriously. AlCl3 was more suitable to co-produce furfural and cellulosic residue from bagasse.

Abstract

In order to develop a process for the simultaneous production of furfural and easily hydrolyzable cellulose, the degradation of sugar cane bagasse in a single aqueous system and in a 2-methyltetrahydrofuran (MTHF)/aqueous AlCl3 biphasic system was studied. In single aqueous system, the influence of acid species (FeCl3, HCl, and AlCl3) on furfural production and cellulose degradation was investigated at 150 °C. FeCl3 and HCl promoted furfural production from hemicellulose but with severe cellulose degradation. AlCl3 decreased cellulose degradation with considerable furfural yield and high glucan content in solid residues. The role of NaCl in furfural production and cellulose decomposition was also investigated in the single aqueous system using different acids as catalysts. Addition of NaCl significantly promoted furfural yield but also accelerated cellulose decomposition when FeCl3 or HCl was used as catalyst. In the AlCl3-catalyzed system, NaCl had less influence on residue yield and its composition, although NaCl also promoted furfural production. The influence of MTHF on furfural yield, residue composition, and enzymatic hydrolysis of residue was also studied. Under the best conditions (0.45 g of bagasse, 9 mL of MTHF, 9 mL of water, 0.1 M AlCl3, 150 °C, 45 min, and 10 wt % NaCl), 58.6% furfural was obtained while more than 90% of cellulose remained in the residue. The organic phase was separated from the aqueous phase directly by decantation. After reuse of organic phase for 3 cycles, 11.5 g/L furfural was obtained. The catalyst-containing aqueous phase could be reused directly after decantation of the organic phase without loss of activity. The obtained residue was easy to hydrolyze and produced 89.3% glucose yield after 96-h enzymatic hydrolysis at low cellulase loading (30 FPU of cellulase/g glucan).

Source:

- Chinese Academy of Science, 14 November 2016

- ACS Sustainable Chemistry & Engineering, 30 August 2016...